In the paint and coating industries paint adhesion testing is often used to determine if the paint or coating will adhere properly to the substrates to which they are applied.

Mil spec paint adhesion test.

Other related tape adhesion test methods include din en iso 2409 paints and varnishes cross cut test fltm bi 106 01 gm 9071p gmw14829 iso 2409 and navistar mpaps gt paint gt 5a.

Method a x cut and method b cross cut.

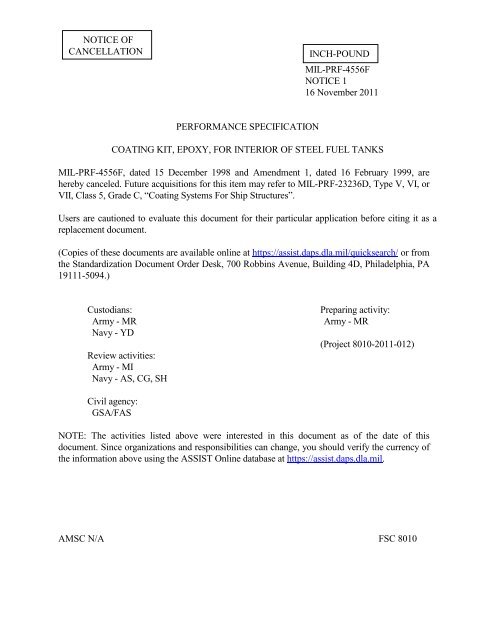

To spec at defense logistics agency dla mil cadmium detail how adhesion testing is to be performed.

The adhesion test kit for paint and coatings contains all of the tools and materials needed except for the multi tooth cutter blade for conducting adhesion tests on paints applied to a flat uniform surface in accordance with astm test method d3359 method b and din standard no.

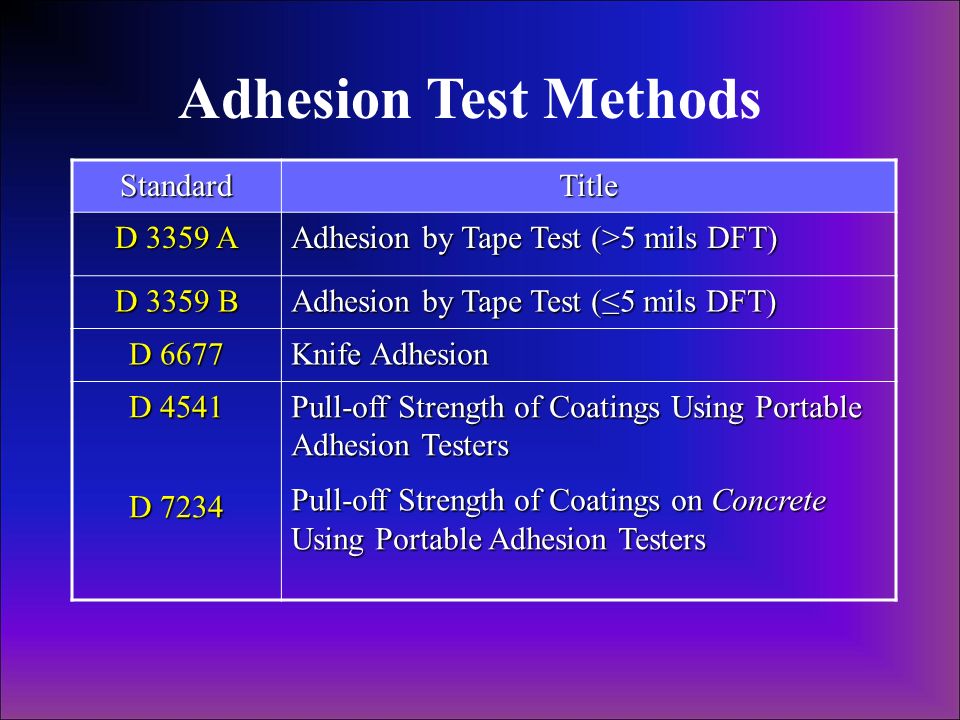

Cross cut test scrape adhesion pull off test and others.

Those supplied to the defense industry however are expected to survive a much wider barrage of environmental tests and often chemical exposure tests as well.

This procedure can also be administered on site and provides quantitative results in.

The test description information in the following section was extracted from an article written by raymond tombaugh sr.

3 2 test method b a lattice pattern with either six or.

Iso 2409 paint and varnishes cross cut test4 3.

Military specifications for plating such as qq p 416 link by ed.

Coatings consultant with kta that was posted to kta university in 2018 titled coating adhesion testing using knife tape methods two test methods are described in astm d3359.

In this test a coated specimen is biaxially stretched a given distance in an appropriate machine adhesive tape is applied to the deformed area dome and then pulled off and the amount of coating removed is.

For instance plate a test coupon subject it to chromate treatment if required prime and paint using your normal paint system.

Summary of test methods 3 1 test method a an x cut is made through the film to the substrate pressure sensitive tape is applied over the cut and then removed and adhesion is assessed qualitatively on the 0 to 5 scale.

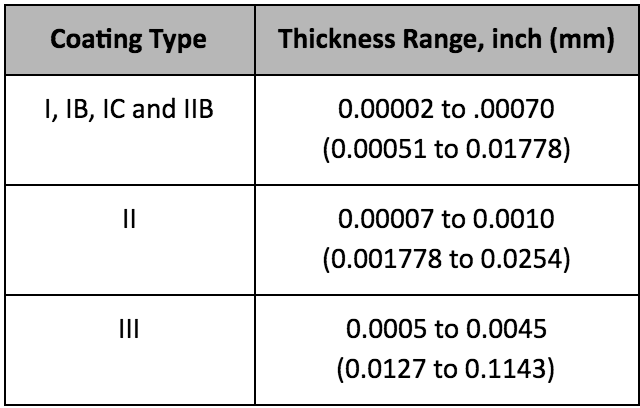

Mil features a wide variety of coating types.

The appearance adhesion wetability corrosion resistance wear resistance scratch resistance etc of a part can be upgraded.

The aim of applying coatings is to improve surface properties of a material.

They may be applied as liquids gases or solids.

Optical coatings provided for commercial applications often require no more than basic adhesion or abrasion testing to validate reliability beyond spectral performance.

Formability and adhesion testing of factory applied zinc rich primer chromate complex coatings on steel is described in astm 4146.

For additional test methods related to astm d3359 we invite you to read more about our coating testing services.